What you can see in current market

-Very bad quality

-Downtime very high

-No robust design

-Difficult for maintenance

-Difficult for operator

-Ergonomic

-Bad project manage

-Not really using quality system

-No standardization

-High turn over

-Internal management very bad

-IE experience

Background

Mainly in china the problem is that we lack of creativity, we are good at copy and do a fast project. But many times we are doing a bad work. FOF thinks if we can not understand very well what we are doing, we will never do a good work. When we design a line or machine, We consider we are the final customer, consider we are the operators in the line, consider we are the quality manager, consider we are the investor of our customer’s company, We always want to provide you one best quality line with lowest invest, We don’t want to waste any cents of our customers.Our team have been worked in automotive area many years, We have a lot of experience in quality system/ Industrialization /Maintenance / project management.

Thinking and make a good plan before doing is the general rules of FOF. During all the phases, Thinking is always the most important!

Concept of FOF

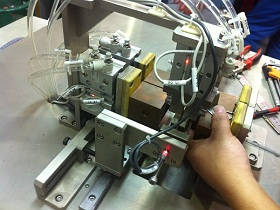

-Robust

-Standard

-Easy

-Focus on process control

-Design is the most important

-Thinking before doing

-Team work